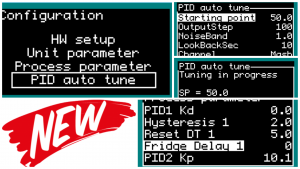

Happy to announce after 2 weeks from SmartPID launching that the second application on top of the SmartPID platform is nearly ready and is completely dedicated to home brewing process automation

What is new and different compared to the standard basic application (smart thermostat)?

Substantially Smart Home Brewing App adds to a standard temperature control features all the process automation and workflow to manage all typical steps for beer making. We have customized vertically the SW for the specific application leveraging all the basic features available on the platform

Each vertical application has off course it’s own set of data, process parameter and configuration and so is the smart home brewing app that execute all process steps according to in memory “recipe”and controls HW resources (heating elements, pump/stirrer, buzzer ) in automatic way

These are main characteristic of the smart HB application

- Single vessel (BIAB/RIMS) or two vessel (MASH + HLT) process management

- Electric heating (PID/PWM) or Gas Fired heating (ON/OFF)

- Recirculating pump or motorized mixer management

- NTC/DSB18B20 temperature probe

- Internal or external (in recirculating circuit) temp probe position

- Step Mash management (mash in/out and 6 step mash)

- Boil management with overboil and power control (electric only)

- Hop addition alarms

- Whirlpool management (hot or cold)

- Cooling management

- Full recipe management (new / edit /clone /delete)

- Mash profile

- Boil duration and hop addition time

- 10 possible in memory recipes

- Delay start for brew day programming

Off course the brewing application benefit of all common features

- Log of all process data locally in the EEPROM

- Push of process data via wifi to thingspeak server

- Download of process data via USB (CSV format)

- Web visualization of process data

- SamrtPID dedicated smartphone app for data visualization (android only)

If this is not enough the development roadmap foresse other uniques functions in particular the possibility to define the process parameter and recipe via web or smartphone interface and upload via wifi to the controller.

Even if it’s very easy to configure smartPID via local menu the possibility to have a web user area with all parameters and recipe as well all the log data of previous brew day we believe is a real plus. In order to simplify the recipe process from definition to run mode also import of mash and boil profile from major SW like Beersmith is in feasibility stage

In the video a complete overview of the configuration steps and a full brewday simulation trough the EMULATOR

stay tuned

arzaman

WHEN AND WHERE WE CAN BUY SmartPid?TKS

coming soon !

register site newsletter and FB page to get early bird offer

Wow! Looks great! Is it also possible two mash two kettles at the same time with one SmartPID controller?

Smartpid has two independent control channels and iiin the brewing application you can control mash/boil vessel and sparge water vessel

Stay tuned

Davide

assolutamente si

sto lavorando a una versione plug-n-play con semplice rimozione del STC200 originale e inserimento SmartPID per avere completo controllo di processo, automazione della pompa, gestione ricette, log dei dati di cotta via wifi etc..

stay tuned

arzaman

Salve, un domanda, lo Smart Homebrewing può essere installato su il grainfather?

Grazie e complimenti per il lavoro che svolgere.

si certamente puo’ sostituire STC200 e far diventare il GF un perfetto sistema automatico con gestione ricette, gestione remota etc…

sto lavorando a due ipotesi di integrazione plug and play a minimo impatto…a breve dettagli

arzaman

Hi, short question. I have two pots:

1. Mash tune – 2kW

2. HLT – 3 kW

Would it be possible to connect both pots to the SmartPID? If so – how?

Regards

absolutely yes…two indipendnet channels one for mashing with full automation and one for HLT with just temperature control

have a loog to this schema