As we have described in the post “flexible configuration and setup” trough HW set up SmartPID can be adapted to mange different applications

below some example to illustrater the flexibilty

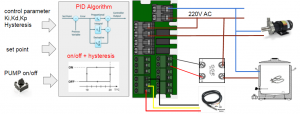

Single channel – PID (on/off) control mode – heating + pump

SmartPID reads temperature from 1 probe and drive the heating element in order to get the setup temeprature

Possible heating output configurations

- SSR for electric heating [PID+PWM control algorithm]

- 220V AC relay for electric heating [ON/OFF algorithm]

- Direct solenoid valve drive for GAS heating [ON/OFF algorithm]

Manually drive the PUMP (soft switch) with tow possible configurations

- 220V AC realy pump drive

- 12V DC direct pump drive

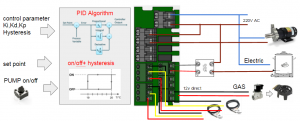

DUAL channel – PID (on/off) control mode – heating (gas or electric)

SmartPID reads temperature from 2 probe and drive 2 heating element idipendently in order to get 2 different set up temperature

Possible heating output configurations

- 1 x SSR for electric heating [PID+PWM control algorithm]

- 1 x 12V direct solenoid valve drive for GAS heating [ON/OFF algorithm]

Manually drive the PUMP (soft switch) with tow possible configurations

- 220V AC realy pump drive

- 12V DC direct pump drive

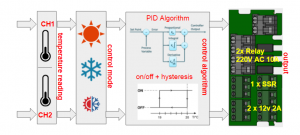

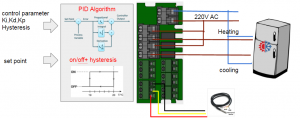

DUAL channel – ON/OFF control mode – thermostatic

SmartPID reads temperature from 1 probe and drive one heating element and one cooling element in order to keep temperature stable (fermentation chamber)

Possible heating output configurations

- 220V AC relay for electric heating [ON/OFF algoritm]

- 220V AC relay for electric heating [ON/OFF control algorithm]

the possibility of configuration are really endless !